CO2 consumption in industry: Renewable energies for buildings and processes

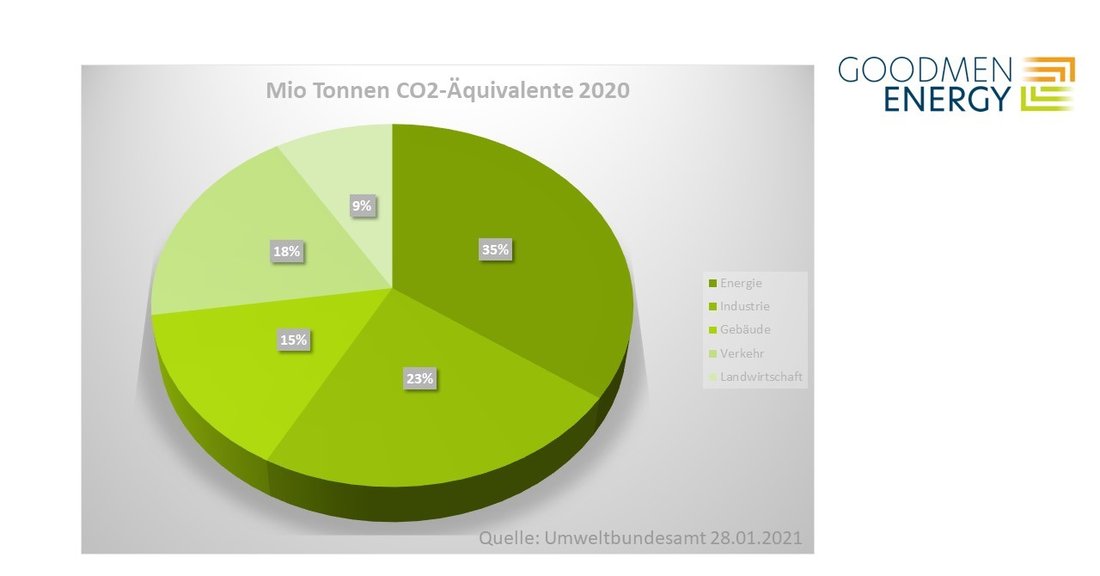

About 15 percent of the total (direct) carbon dioxide (CO2) emissions in Germany come from the building sector - excluding embodied energy and energy consumed during operation (as of 2021, source: Federal Government). The industrial sector is even responsible 23 percent of greenhouse gas emissions. Furthermore, the German industry uses almost a third of the final energy.

Since Germany is aiming for a climate-neutral and greenhouse gas-free economy by 2045, there is an urgent need for action here.

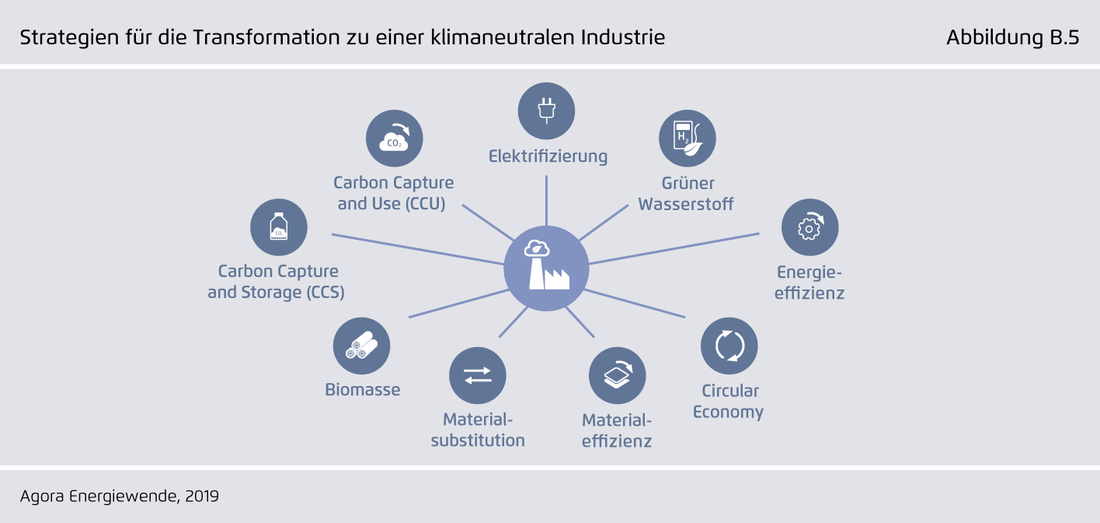

CO2 savings in industry: opportunities

2/3 of the greenhouse gas emissions from industry in Germany are caused by energy production. Consequently, this means that to save CO2, a

- switch from fossil fuels to renewable energies should take place. This is possible in many industries for both heat and electricity generation. It also makes sense to

- reduce energy consumption - both in the production process and within the building. Other factors that can be considered are the

- recovery of energy on the one hand or the

- capture of harmful gases such as CO2 on the other.

1. Switch to renewable energies

At goodmen energy, we have already been able to advise and support several industrial customers. We first look at the consumers, i.e. electricity, heating and cooling demand as well as the temperature level. We distinguish between electricity/heating/cooling demand for the actual production process and as part of the building supply.

1.1 Efficiency improvements in heating and cooling supply

We achieve this through

- the use of heat pumps,

- the use of anergy (whereby heat and cold are provided in equal measure with the help of a heat pump - without additional cooling units or air conditioning),

- lowering the temperature level (where possible).

For a large industrial site with a consumption of up to 200 GWh of electricity, heating and cooling efficiency improvements represent a rather small share. Thus, at first glance, our contribution to making the production site CO2-free often seems quite small. But even if we can only save pone-twentieth here, the share is about as large as 3,000 single-family homes with heat pumps would be supplied with for a year!

There is often little free space at existing industrial sites. Highly innovative approaches to heat generation help to fully exploit the potential anyway. Geothermal probe storage, for example, require little space and can be thermally regenerated very well by PV(T) systems and industrial waste heat. The intelligent combination with an ice or hydrogen storage system also offers interesting and economical solution options here.

1.2.Use of renewable energies for electricity generation

Very high CO2 savings can be achieved in electricity. On industrial locations, the electricity demand is usually very high. Here, often not only general electricity saving potentials are offered, but above all an alternative power supply via PV systems and wind power as a substitute for the previous fossil fuels.

1.2.1 Photovoltaics (PV) - mandatory for industrial sites

A PV system at an industrial site is always worthwhile, says our general manager Markus Pröll. Factories often have an all-day, all-year-round electricity demand that is far higher than what a PV system can supply. This means that every kilowatt hour that comes from the PV system on the roof is consumed directly in the production process. Economically, this is extremely attractive, as one is not dependent on feed-in prices of energy into the public grid and at the same time has to purchase less electricity from the grid.

Unfortunately, just equipping roofs or façades with photovoltaics is not enough to meet the high energy demand. After all, how much solar energy can be generated? Here is an example based on our practical experience: At goodmen energy, we are currently planning energy-saving measures for an existing industrial site with electricity consumption of 5 GWh. For this purpose, we have planned PVT for all available roof surfaces (6,000 m2). In this way, we generate one GWh of electricity. This means that we can only cover 20% of the demand from solar power through our measures on-site measures. With higher electricity consumption, this share even decreases.

However,if enough electricity cannot be generated on site, other solutions have to be found, such as PV or wind farms.

1.2.2 Wind power - industry-owned wind farms

Particularly for industrial sites, it makes sense to build wind farms as close as possible to the local area in order to cover the electricity demand. Companies could (and should) become electricity producers themselves. Whether they are also operators of the wind farm, act as investors or use a contractor is not primarily decisive.

What is decisive is that the "entrepreneur = electricity producer" equation is a business case in which companies benefit from far more favourable electricity production costs than if they purchased electricity from other sources - even if it is only because the margins are eliminated.

"Companies should take care of the procurement of electricity from renewable energies independently and at an early stage. I think it is wrong to leave the solution to this problem to the state," believes Markus Pröll. And furthermore: "If industry has to take care of electricity procurement itself, the pressure is also higher to manage it efficiently and then it is more likely that we can achieve the goal of a climate-neutral industry by 2045. If, on the other hand, we continue to take responsibility as a nation for the industry's misbehaviour, then the climate turnaround will not succeed."

2. Reducing energy consumption: More efficiency in the production process

Theoretically, there is also great potential for saving energy in the production process. So far, the focus has not been on curbing energy consumption, but on optimising the production process. Due to the cheap energy prices promoted by politicians, industry has tended to give less thought to consumption.

However, the conversion to renewable energy sources is not without problems: conversion measures, necessary high investments and losses in productivity place a heavy financial burden on existing production companies in particular. Therefore, massive interventions in existing buildings and during operations are extremely difficult. Moreover, savings must not be made at the expense of product quality.

It is easier to start with new factory constructions, where the question of energy efficiency must be taken into account from the very beginning.

3. Recovering energy: Making good use of waste heat through sector coupling

A lot of (waste) heat is generated in the production process. This is released into the building and heats it up. Instead of simply ventilating the heat away, as is currently done far too often, it is important to make it usable: keyword heat recovery.

Waste heat is anergy, i.e. it has a temperature level that is usually not directly usable in terms of energy. Nevertheless, we can use it, for example, to store it directly in geothermal probes on site and thus promote soil regeneration when heat is recovered from geothermal sources.

At goodmen energy, we would use waste heat from industries to feed into a local cold district heating network. This makes the waste heat available to residential buildings by regulating the heat pump sources with it. So instead of losing the anergy surplus in the production process, our concept for the future is to link industrial sites with residential areas and thus run cold grids.

Alternatively, less waste heat may be produced in the future: New processes and materials help to increase energy efficiency and reduce heat emission. Even an optimised motor, a new drive or a more efficient pump can make a big difference.

4. Carbon Capture – catching CO2

Unfortunately, CO2 emissions cannot be avoided in every sector. For example, in the production of cement, there is no way to change the process without losing fundamental properties. This means that there is no technological alternative to the CO2-intensive burning processes. To solve this dilemma, so-called CCUS technologies (Carbon Capture, Utilisation and Storage) could help: With these, the CO2 released during fossil combustion processes can be captured and stored and can then be used and bound as a raw material in other processes, for example to produce e-fuels.

"The problem is, however, that in the end the carbon is released again, even if it supports two processes here instead of just one. For me, the solution is therefore to avoid CO2. For me, capturing CO2 and then storing it in caverns is, like final storage in the nuclear industry, not thinking it all the way through," says Markus Pröll.

A lot of research is currently being done on this topic. In the coming years and decades, this will certainly result in new solutions. Overall, industrial processes must become lower in CO2 and more flexible so that the sector can become greenhouse gas neutral and the climate goals can be achieved.

Bottom line

So, can these measures succeed in making industry climate-neutral and CO2-free by 2045?

Technically, we believe it is feasible. If there is also the political and entrepreneurial will to start these efforts immediately and without delay, the changeover can still be achieved within the given time frame. A strong economic pressure due to rising energy costs will certainly have a supporting effect here.

As goodmen energy, we ask ourselves where we can achieve the greatest impact with our actions. Of course, this is much higher in industry than in the renovation of single-family homes. But for us, every effort counts, because all efforts are a step in the right direction - sometimes smaller, sometimes bigger. There is enough work to be done - we are up to it.